A growing challenge for concrete producers is achieving predictable performance with a growingly diverse range of concrete materials. As the composition of concrete materials widens, the possibility for unpredictable performance increases. Concrete mixtures are becoming more complex for a variety of reasons:

- demand for more challenging engineering properties such as self-consolidation and higher early strengths

- the need to lower the carbon dioxide (CO2) footprint of structures

- a growing shortage of certain concrete materials such as acceptable aggregate

- use of more complex admixture systems

When using chemical admixtures, concrete producers need to be aware that certain admixture-cementitious material combinations may not provide the intended results, such as adequate slump increase or water reduction. Having spent 34 years with the R&D group of a global admixture company, I know that investigations were occasionally conducted to understand the cause of cement-admixture performance problems. This concern for concrete materials incompatibility has prompted the development of methods to diagnose the cause of admixture-related performance problems, and also to help concrete producers anticipate unexpected changes in concrete properties. ASTM Committee C09 on Concrete is now balloting a mortar method on how to systematically test various admixtures, cementitious materials, and fine aggregates.

The Classic Incompatibility Problem

Water reducers are by far the most commonly used chemical admixture for concrete and as a result, incompatibility problems with water reducers has been extensively investigated. A common problem occurs when a concrete producer switches cements and finds that his standard 4000 psi mix, calling for a lignosulfonate-based ASTM C 494 Type A water reducing admixture (WRA), exhibited far more rapid slump loss than with the prior cement.

A pail of cement and a bottle of admixture were provided for evaluation. Both the cement and admixture conformed to their respective ASTM specifications. A modified version of the ASTM C359 Early Stiffening of Mortar test was selected as a convenient method to investigate slump loss since this is an established procedure for determining a cement’s tendency for false or flash set. The test method can easily be modified to include admixtures. As a note of caution, the results from any paste or mortar test should be carefully interpreted since the results only suggest possible causes and solutions that might be occurring with actual concrete production and use.

The modified C359 procedure calls for preparing a mortar where a chemical admixture can be added with the mix water or after the cement and mix water have been mixed together. The mortar is then mixed for a prescribed time, followed by placing the mortar in a rectangular container at a depth of 50 mm. The mortar is then tested for the rate of stiffening with a penetrometer. After four readings taken at three, five, eight, and 11 minutes from initial batching, the mortar is remixed, placed in the container for a second time, and tested with the penetrometer. Penetration readings of 50 indicate a highly workable mortar, while a reading of zero corresponds to a completely stiffened condition.

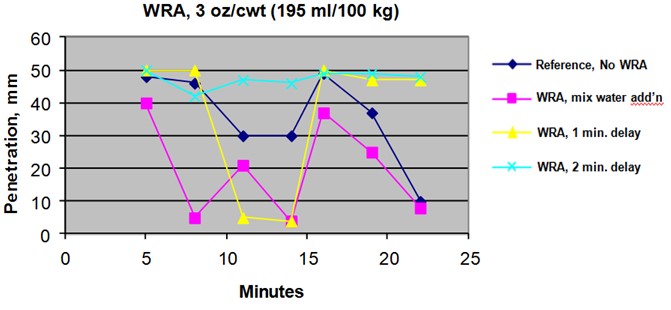

In the case of the reported rapid slump loss problem, the following four mortar mixtures with a 0.30 water-cement ratio were prepared and tested for penetration versus time:

- Control mortar without admixture

- Mortar with the WRA diluted in the mix water (mix water addition of admixture)

- Mortar with WRA added one minute after cement and water have mixed

- Mortar with WRA added two minutes after cement and water have mixed

Plots of mortar penetration versus time for the four mortars are shown in Figure 1. The control mortar exhibits an immediate loss of workability based on a drop in penetration readings indicating a false set tendency. After remixing the mortar at 11 minutes, the mortar continues to stiffen possibly suggesting that concrete produced with this cement could have a slump loss tendency.

For the second mortar mixture with WRA added with the mix water, the initial penetration is actually lower and the mortar stiffens more rapidly than the control mixture. This comparison of the first two mortar mixtures represents classic cement-admixture incompatibility. Instead of the WRA producing a more workable mortar, the mortar actually stiffens faster than the control.

For the third and fourth mortar mixtures, the admixture was added one and two minutes, respectively, after the cement and water were allowed to mix. The progressively higher penetration readings with the delayed addition mode again point to a cement-admixture compatibility issue when the WRA is added with the mix water.

The Chemistry

Due to all the complex chemical and physical processes that occur during initial cement hydration, we don’t fully understand the cause of this cement-admixture incompatibility. One factor seems to be the formation of calcium aluminate hydrate (C3A) during the initial minutes after cement and water are in contact. The hydration product that we would normally like to see form in this initial phase is a mineral called ettringite. But if a sufficient amount of the inter-ground gypsum used to control flash set is not present when the cement and water are mixed together, the highly undesirable aluminate hydrate forms. Aluminate hydrates generate a significant amount of heat, cause rapid loss of workability, and strongly and irreversibly bind many chemicals in concrete admixtures.

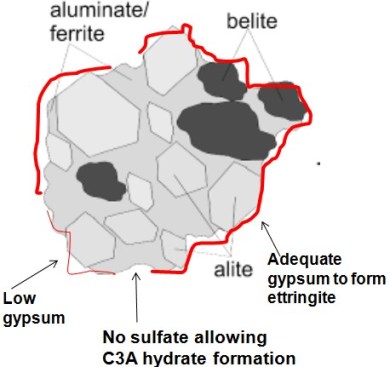

Figure 2 – Cement grain with different layer thicknesses of inter-ground gypsum (red line); sub-microscopic areas on the cement surface lacking gypsum allow direct hydration of C3A to form C3A hydrate.

Figure 2 illustrates one possible model of how aluminate hydrates may form. During the grinding of cement clinker with gypsum (red line), it may be that sub-microscopic areas of the cement surface have a deficiency of soluble sulfate ions from the gypsum. At these sites, the highly reactive aluminate phase can react directly with water to form calcium aluminate hydrate. The portion of the WRA not adsorbed by the aluminate hydrate phases rapidly disperses the cement, which in turn makes more reactive sites available for the calcium aluminum hydrate to form. This process can be responsible for rapid slump loss. Thus, the mortar, prepared with the admixture dissolved in the mixing water, can actually have more workability loss than the control mix because of the continued early formation of aluminate hydrate.

Another way to understand the problem with mix water addition of chemical admixtures is that the water reducer for this particular cement appears to create an imbalance in the rate of sulfate available to control C3A reactivity as the cement begins to hydrate, enabling the aluminate phase of the cement to form aluminate hydrate rather than ettringite. The aluminum hydrate rapidly binds many types of chemical admixtures rendering them unable to function. Aluminate hydrate also rapidly builds a structure within the freshly mixed concrete contributing to rapid slump loss.

Slump Variability

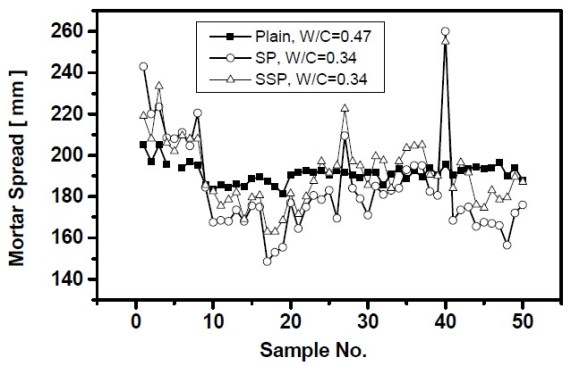

Figure 3 – Mortar spread tests illustrate how superplasticized mortars can exhibit far greater variability in spread versus the control mortar without admixture.

Figure 3 illustrates an example of highly variable cement-admixture performance. A precast concrete producer was experiencing a lot of variation in slump using two different superplasticizers, a melamine sulfonate formaldehyde condensate (SP) and a polycarboxylate (SSP) added with the mix water. A number of cement samples that had been kept for evaluation were tested in mortar mixtures. The mortar flow results indicate fairly uniform mortar flow without any admixture, but significant variation with either the melamine sulfonate or polycarboxylate.

The Fix

An easy and effective fix to this cement-admixture problem is to delay the addition of the admixture until after the cement and water have mixed. While this may not always be possible with a concrete producer’s batching process, delaying the admixture addition can improve dosage efficiency (that is, higher slump or greater water reduction) and result in more consistent batch-to-batch performance. Note the significantly improved results in Figure 1 for mortars prepared with delayed WRA addition. Even the early stiffening of the control mortar is eliminated by a 2-minute delay in WRA addition.

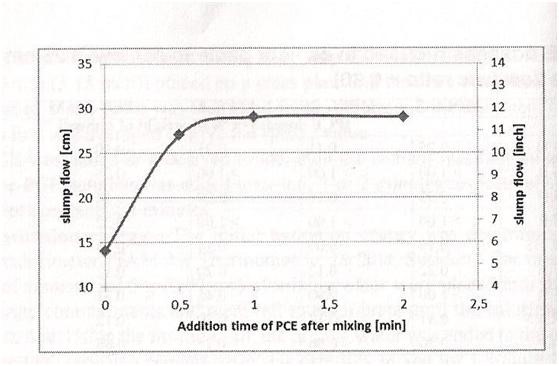

Figure 4 – Slump flow as a function of the addition time of a polycarboxylate water reducer shows that flow stabilizes after about 45 seconds.

Another good example of how delayed addition improves workability was seen in a study to design a polycarboxylate polymer (PCE) with reduced cement sensitivity. Using a simple paste mix with high early strength portland cement, and a 0.30 water-cement ratio, a fixed dose of a polycarboxylate superplasticizer was added with the initial mixing water and at various delay times. The slump flow results are shown in Figure 4 and indicate a progressive increase in paste flow, reaching a consistent value at 50 seconds. Furthermore, the slope of the line prior to 50 seconds suggests that the potential variability in workability depends on the extent of the very initial hydration of the cement prior to when the admixture is added.

The benefits of delayed addition of the admixture can be attributed to allowing the cement to initially hydrate (in the absence of admixture) and form the desired ettringite hydration product versus the highly undesirable calcium aluminate hydrate.

Proactive Test Program

The following approaches can help to minimize the possibility of an unanticipated cement-admixture compatibility problem:

- organize a sampling program to retain samples of cement that can be useful to investigate a performance issue, such as the case with the precast producer

- monitor cement mill certificates and maintain control charts of C3A/SO3 ratio, alkali content, and Blaine fineness — factors that can be related to cement-admixture incompatibility

- establish a mortar or paste quality control program where the performance of cement, other cementitious materials, and fine aggregates can be preemptively checked for their possible impact on concrete performance.

Cement-admixture compatibility issues, while uncommon, can cause significant disruptions to concrete construction. Where possible, a delayed addition of the admixture, will allow many admixtures to perform as expected and consistently. To assess the robustness of the cementitious-admixture system, an active QC program should include one or more mortar tests where routine performance checks can be made. Acquiring an understanding of how and when small changes in admixture dosage can cause major changes in concrete performance will help assure successful production, placement, and service life of concrete.