SCC was used for the Trump International Hotel and Tower in Chic…

The robustness factor

Because of the high flow properties of SCC mixtures, robustness becomes a critically important attribute of SCC as the heavier materials in the concrete mixture can more easily settle resulting in segregation. Robustness is understood to be the capacity of a concrete mixture to maintain uniform composition following some change in mixture composition, mixing procedure, and handling. Load-to-load variations in water content, resulting from changes in sand moisture, drum water content, and water demand of the concrete materials, can be prime causes of segregation if the SCC mixture does not have sufficient robustness.

Workabilty box concept

One approach to evaluating the robustness of a particular SCC mix design in terms of impact of moisture variation on segregation is to proactively challenge a properly proportioned SCC mixture with sequential additions of water until the moisture tolerance level is exceeded, and the mixture undergoes unacceptable segregation.

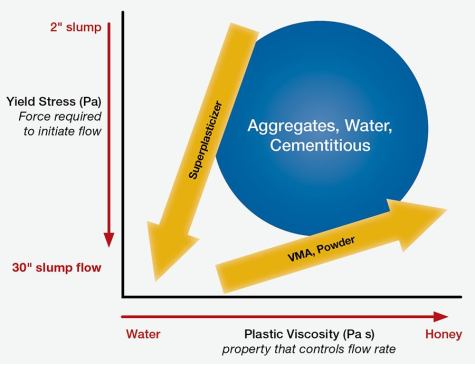

Similarly, the mixture can be prepared with several lower water contents to understand at what water/cement ratio the mixture will exhibit insufficient slump-flow (placeability). For each change in water content, an SCC mixture is prepared, and rheological measurements and stability indicating tests such as the Visual Stability Index (VSI) described in ASTM C1611, the ASTM C 1610 Column Segregation, and/or the C1712 Penetration Depth test are performed. Using a plot of the yield stress versus viscosity (or slump-flow versus T20), a box, referred to as the “Workability Box” can be drawn around those clusters of points that represent both adequate concrete flow and stability. Data points outside the box either have poor segregation resistance or inadequate flow properties. Figure 3 illustrates the application of the workability box where an SCC mixture with unacceptable stability (Table 1) is adjusted with incremental changes in superplasticizer and VMA dosages to achieve acceptable slump-flow and flow rate properties, and stability performance (Table 2). A box is then drawn around the data point which represents a zone of rheological properties where the SCC mixture will provide acceptable performance. The key strategy in using the workability box is to understand what changes in the SCC mix (as well mixing and handling processes) will cause the mixture to fall outside the workability box parameters.

Thus, the resulting workability box can serve as a valuable quality control tool to minimize the possibility of rejected loads. Ideally, the goal is to design SCC mixtures with such robustness as to maximize the dimension of the workability box.

In conclusion, the probability to consistently produce robust high quality SCC that meets job requirements can be significantly increased by proactively quantifying the variables that would cause a properly designed SCC mixture to fail. The workability box concept can be a useful approach to designing robust SCC mixtures with predictable performance. In terms of optimizing the admixture system for SCC, do not rely solely on the selected admixtures, especially the VMA, to assure consistently acceptable performance. The admixture supplier should be regarded as a valuable resource to optimize both the SCC mix design and admixture selection based on the properties of the job materials and requirements.

Dr. Ara A. Jeknavorian is a consultant with Jeknavorian Consulting Services, Chelmsford, Mass. He received a Ph.D. in Analytical Chemistry from the University of Massachusetts-Lowell. He is a Fellow of both the American Concrete Institute and ASTM, and has served as past chair of the ASTM chemical admixture sub-committee. Prior to starting his consulting practice, Jeknavorian was a member of the R&D group of the W.R. Grace Co., where he was responsible for the development of new chemical admixture technologies and products. He is an inventor on 19 patents and has published over 40 articles dealing with chemical admixtures. His research interests include admixture technology development, probing cement-admixture interactions, and troubleshooting unexpected cement-admixture performance.

More from Concrete Construction Magazine

-

Solution for Crumbling Concrete

3 MIN READ

-

-