5. Technology

Connect the Dots

Imagine a person knocks on your door and asks, “Mr. Smith, your house has my company’s windows. Would you like to buy replacements?” Odds are, your answer would be no.

Now imagine that same person knocks on your door and says, “Mr. Smith, I know your windows were built at our South Dakota factory on a Tuesday and shipped to Joe’s Lumber, where Bob Miller did the installation 12 years, seven months, and 18 days ago. Since then, this neighborhood has seen 23 hailstorms, two tornadoes, 43 days of gale-force winds, and 256 days in which the temperature rose or fell at least 37 degrees. We estimate your windows are 38% less efficient than today’s models, costing you an average of $348 in extra heating and cooling costs annually. And your insurer has a deal in which your property rates would fall 8% if you could reduce the possibility of broken windows. Would you like to buy replacements?”

Such is the power of Big Data. Our ability to store and cross-reference information across diverse resources promises to be one of the biggest change makers in the next 30 years. The communications breakthroughs of the past three decades have largely been linear—linking one person with another, or perhaps sending the same generally unchangeable message to many people simultaneously. In contrast, the future will be about creating a matrix in which information is not only customized but also ever changing based on a potentially unlimited number of factors.

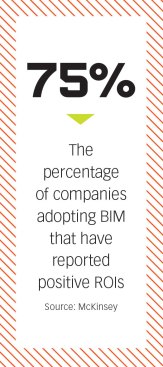

The idea of sharing data between companies typically has revolved in the past around bar codes. That technology is likely to continue playing a role, but in some cases blockchain may be used, particularly for higher-value or more-official initiatives such as certifications. Susan Piedmont-Palladino, a professor at Virginia Tech who curates exhibitions at the National Building Museum, suggests that the building information modeling software used to design homes also can serve as a repository for information on all the materials used in the house.

“BIM isn’t just a design tool. It’s also a stewardship tool,” she says.

On the manufacturer level, too, the idea of knowing what you have is taking hold. “There’s going to be a social expectation that we can report on all the products we’re using” in the manufacturing process, predicts Lynn Wilson, vice president for supply chain procurement at LP Corp.

While all this is going on, big companies like LP are also working on collecting and coordinating internal data. In the past, LP supply chain specialist Allan Burk says, a business like his struggled to move vital information within the company, such as trends with product orders that people in the mills could use to anticipate demand, or how adjustments in trucking rates could influence sales reps’ quotes.

“In the past, we worked with averages,” he says. “Now, we need more precision.” In essence, the more you know, the more you can earn.

Coming Soon: Bendable Smartphones

Some advances won’t need 30 years to happen. The internet is blooming with stories about Samsung’s plans to sell a phone that can bend and even fold. The key is a display screen made of plastic rather than the high-strength Gorilla Glass that’s so common today. Samsung has been teasing customers with reports about the impending release of its bendable Samsung X. The latest talk is to expect a launch in 2019.

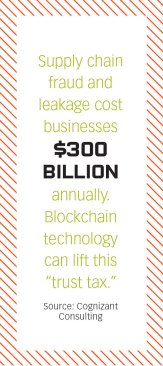

Chockablock-Chain

Trust, but verify,” President Ronald Reagan used to say when dealing with the Soviet Union. LBM dealers have long tried to do the same, but while the trust part has been easy, verifying has been tough. This has been particularly true with products from abroad, such as hardwoods from the tropics or drywall from China.

Now comes blockchain, a technology hailed as a potential game changer for tracking and verifying products. But implementing blockchain will require overcoming many obstacles, so odds are its implementation in construction supply will trail that of other industries.

Andrew Lindsey, a market strategist for construction consulting firm Alpha Corp., says blockchain offers its users a 30,000-foot view of how designs and products come to the jobsite and then are used to build a structure.

“One of the easiest ways for a claim to come up is over who held what when and who handed over what when,” Lindsey told concrete construction, a sister publication of ProSales. With blockchain, all that information is time-stamped, can’t be touched or broken into, and is irreversible.

“When you have a very clear snapshot of all that information, you can see what would happen to claims,” Lindsey continued. “You’ll only be interpreting the why rather than the what, which is half the battle.”

Lindsey also said blockchain can help cut scheduling costs and improve cost estimating because its data set is so much more precise than what’s available today.

Kevin Hodge, Epicor’s senior product director for LBM, agrees that blockchain’s potential in construction and construction supply “is quite staggering.” He predicts its first use in LBM will come in the certification of products, such as wood certified by the Forest Stewardship Council.

Beyond such required verifications, the supply chain’s embrace of blockchain could be slow because there’s so much to learn.

“People in the blockchain space don’t know a damned thing about the supply chain, and people in the supply chain space don’t know a damned thing about blockchain,” the FreightWaves website quoted Redwood Logistics chief information officer Eric Rempel as saying at a recent panel discussion. “There is much intellectual property on both sides that has yet to mesh—we’re still embryonic here.”

Hodge notes that blockchain makes sense when you have a unique product, such as a dishwasher, but it’s a lot harder to do with commodities like a 2×4. Still, it could help LBM move beyond using electronic data interchange, one of its most common ways to pass along information today. “This could get us past the things that EDI never could solve,” he says.

“Blockchain has great potential,” Hodge says, “but how it hits us and when depends on when the large people move on it.” Among those big players, the Shelly Palmer tech blog says Maersk uses blockchain to monitor its cargo ships, and British Airways employs it to keep all its displays up-to-date and correct.

-

5 for the Future: Demographics

Projections on how the demographics on the U.S. will change over the next 30 years and what retiring millennials will mean for the residential construction sector.

-

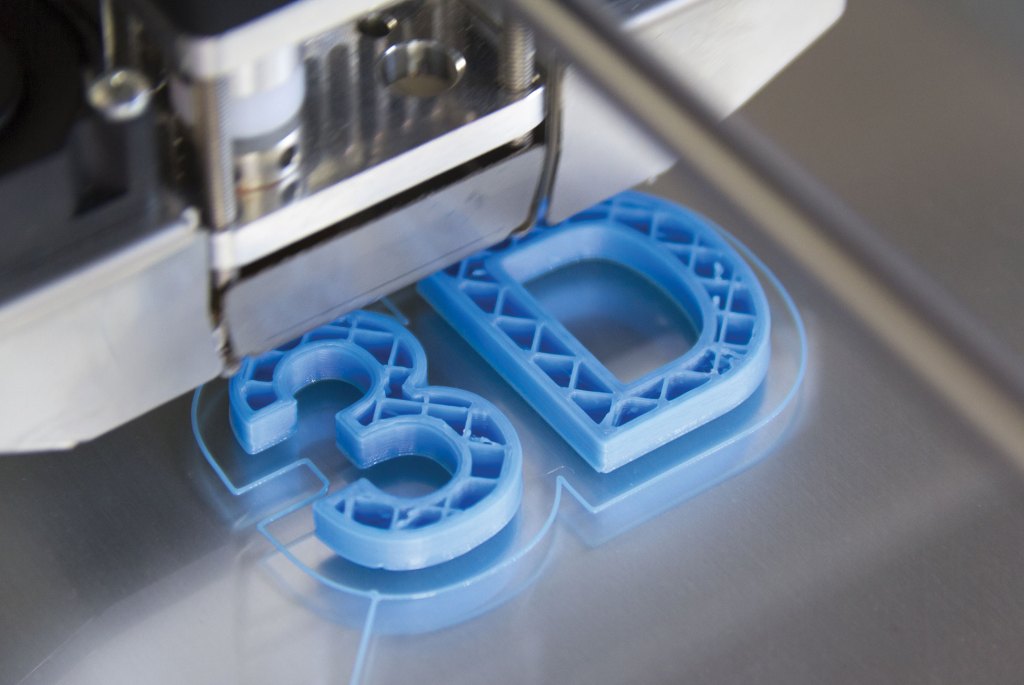

5 for the Future: Construction

A look at what the future holds for 3-D printing, garages in residential homes, and timber in the non-residential construction market.

-

5 for the Future: Environment

Future natural disasters will put a greater emphasis on resilience; building material suppliers could be contributing to community sickness; what rising water levels mean in the future.

-

5 for the Future: Logistics/Products

The future of manufactured homes, trucking and rail transportation, clothing fabric materials, and microscopic building materials are explored.

-

5 for the Future

The key trends that will shape construction and LBM through 2048.