There’s little debate within the housing industry that trade and specialty contractors are increasingly responsible for the actual work done on jobsites. While custom builders and remodelers rely on subcontractors to supplement their superintendents without adding payroll, tract builders hand their trade partners the reins of production while they scout their next development deal. “We work with builders of all sizes and types,” says Catharine Boles, director of sales and marketing for Old Country Roofing in Vacaville, Calif. “That’s the way the market is.”

Nationally, about 22 subs—from masons to roofers—make their way through a typical new-home construction site, according to a 2003 NAHB survey. In addition, two-thirds of all builders subcontract 75 percent or more of their housing production, and 98 percent of the industry subs out at least 25 percent of a home’s construction.

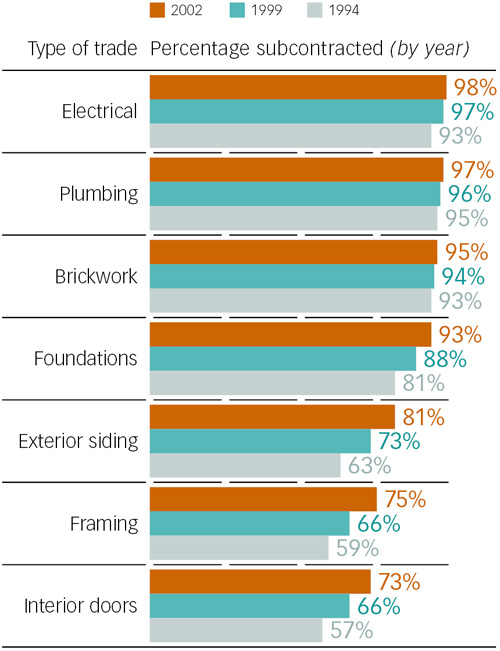

Of course, plumbing, electrical, and brickwork have long been subcontracted trades; increasingly, however, traditional in-house tasks such as framing and exterior siding are contracted out to specialists (see “Subs on Site,” below). In addition, the NAHB survey found that subs are being asked more often to supply both labor and materials, rather than just workers.

But while national trends paint a sweeping portrait of this growing “sub culture,” the picture is fragmented by local product purchasing customs among builders, suppliers, and trade partners. There are also distinct differences between large- and small-volume builders regarding their perspectives and needs for subs. In addition, the influences of national purchasing contracts and installed sales programs offered by suppliers further muddy the water regarding the purchasing power of a builder’s trade partners.

All of this, of course, complicates a dealer’s decision to steer marketing and sales efforts toward subs instead of builders and general contractors. “At a basic level, builders are looking to lower their risk,” says Frank Alexander, a former executive with a national home builder and now director of quality programs (including a trade contractor certification curriculum) at the NAHB Research Center (NAHB-RC) in Upper Marlboro, Md. “Whatever helps a builder achieve that is what [local] suppliers need to support.”

A Changing Landscape Since 1992, the number of home builders nationwide has declined slightly while the ranks of subcontractors—across all trades—have swelled. As of 2002, the latest figures available from the U.S. Census Bureau, specialty contractors numbered about 470,000 firms, nearly four times the number of residential builders and a 28 percent jump in a decade.

The shift to subcontracting more of a home’s construction or remodeling requires a relationship in which, more than ever, trades must adhere to a builder’s or general contractor’s expectations for a higher level of quality, stingier budgets, and tighter schedules. “Our trade partners are integral to our success,” says Tim Shigley, owner of Shigley Construction, a remodeling firm in Augusta, Kan. “We’re working to better define their job responsibilities and get them to understand our expectations and those of our clients so we get the same results on every job.”

As a result, subcontractors are increasingly winning bids based on their takeoff and estimating skills—a proficiency that dealers can certainly help refine or consult, if not entirely assume, as part of supporting trade contractor customers.

Christopher Homes, a custom and luxury home builder in Las Vegas, extends its preferences even further. In addition to dictating specifications, the company also weighs in with (but does not insist on) preferred distributors and suppliers it knows will support its needs for on-time delivery and special orders. “We have a reputation for high-end quality that we need to protect, so the supplier plays an important role, as well,” says Lance Jones, vice president of purchasing.